– source: Wikipedia

– source: Wikipedia

“A knot is never “nearly right”; it is either exactly right or it is hopelessly wrong, one or the other; there is nothing in between. This is not the impossibly high standard of the idealist, it is a mere fact for the realist to face.” – Clifford Ashley

Published in 1944, this is the Bible of knots. Clifford Ashley took notes on knots for over 40 years of his life, and then labored for over 11 years to produce the most comprehensive reference of knots and ropework ever written. Knots in books and articles around the world are frequently referenced back to Ashley’s book. Citations to Ashley numbers are usually in the form: “The Constrictor Knot (ABOK #1249)” or just “ABOK #1249”.

With almost 4000 knots, his work covers basically every type of hitch, bend, stopper knot, lashing, binding knot, and running knot that you can imagine, as well as decorative and fancy knots, trick and puzzle knots, sinnets, marlingspike, and 3-strand splices, among many, many others. This book is exhaustive, and a testament to a devotion and drive to produce something that would stand the test of time. In addition to showing you how to tie the knots, which were all painstakingly illustrated by the author, Ashley helps to explain the history and usage of the knots. The first chapter, ‘On Knots’ is a fascinating look at the history and tools of sailors and ropeworkers – highly recommended reading.

From the first chapter:

“To me the simple act of tying a knot is an adventure in unlimited space. A bit of string affords a dimensional latitude that is unique among the entities. For an uncomplicated strand is a palpable object that, for all practical purposes, possesses one dimension only. If we move a single strand in a plane, interlacing it at will, actual objects of beauty and of utility can result in what is practically two dimensions; and if we choose to direct our strand out of this one plane, another dimension is added which provides opportunity for an excursion that is limited only by the scope of our own imagery and the length of the ropemaker’s coil.

What can be more wonderful than that?”

This book is truly a must-have for professionals who use rope everyday. Of particular note for tree climbers:

From Wikipedia: “The Ashley Book of Knots was compiled and first published before the introduction of synthetic fiber ropes, during a time when natural fiber cordage – typically twisted, laid, or braided rope – was most commonly used. The commentary on some knots may fail to address their behavior when tied with modern synthetic fiber or kernmantle style ropes.”

Clifford Ashley died in 1947. His book is now in the public domain.

The Ashley Book of Knots is available in hardcover from Amazon.com here.

the ashley book of knots archive-org

Download as PDF

source: archive.org

Climb High, Work Smart, Read More.

-TreeMuggs

I would love to hear from you. Please send all comments/questions/hatemail to patrick@educatedclimber.com

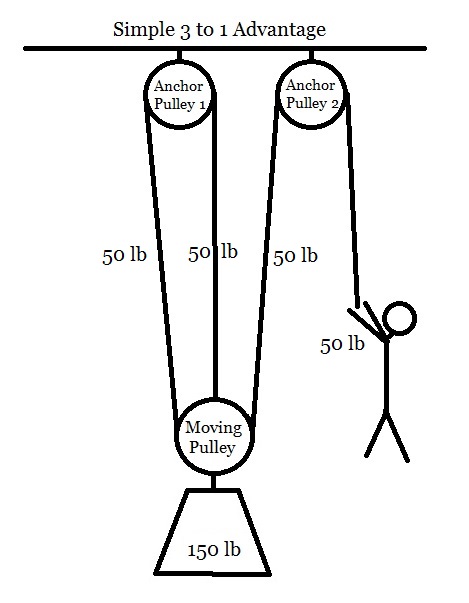

Progress Capture Prusik (installed on load side of anchor pulley)

Progress Capture Prusik (installed on load side of anchor pulley)